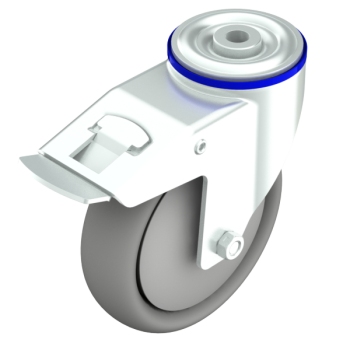

BOLT HOLE castors

The choice of the wheels depends on load, number of transport movements, ergonomic requirements and floor. Wheels are available in various diameters with different bandings such as; nylon, thermoplastic and polyurethane. Also for ESD applications the right castors are available. All castors are equipped with ball bearings for low starting and rolling resistance. By placing an insert net into the tube the castors can be easily connected

Recommended

Recommended

Recommended

Outgoing

Outgoing

Outgoing